When leaders hear that most problems belong to the system, it can sound like an accusation—or worse, an invitation to lower standards. So nobody’s lazy? Nobody incompetent? That reaction is understandable. It’s also costly. The real question isn’t whether individuals ever contribute to problems. It’s whether leaders are aiming their time and energy at the place where improvement actually lives. Today we’ll explore why blaming workers feels decisive, why it so often misses the mark, and how a clearer way of thinking leads to better results.

Why blaming the worker feels obvious

W. Edwards Deming never asked leaders to take anything on faith. He asked them to study evidence. Yet his ideas are frequently dismissed as naïve because they seem to collide with lived experience. Leaders have seen missed deadlines, chronic rework, and visible disengagement. They’ve had hard conversations. They’ve replaced people—and sometimes things really did improve.

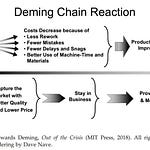

So when Deming says that most problems belong to the system, it can sound like an absolutist claim that denies reality. It isn’t. What Deming challenged was a habit of mind: explaining outcomes by pointing at people instead of understanding the conditions that shape their work. When the same problems repeat across teams and across individuals, he argued, we are not observing human failure. We are observing a system doing exactly what it was built—and allowed—to do.

To see how this misunderstanding plays out, consider a familiar manufacturing setting.

Reconsidering where problems come from

Midwest Components manufactures precision parts for heavy equipment. Late orders have become routine. Scrap rates swing from week to week. Supervisors are worn down by constant firefighting.

At the center of it are two leaders. Jack, the plant manager, came up through operations. He prides himself on knowing the floor and holding people accountable. Maria, the operations director, was brought in to stabilize performance and reduce chronic volatility.

Jack is blunt about his frustration. “Look,” he says, “I don’t buy this idea that it’s all the system. I’ve been here twenty years. I know when someone just doesn’t care.”

Maria doesn’t dispute that people matter. “I’m not saying people don’t matter,” she says. “I’m asking a different question. If we swap operators between lines and the problems stay with the line, what are we really seeing?”

They review six months of data together. Late orders spike predictably at month end when schedules compress. Scrap jumps whenever a specific alloy lot is introduced. Training records show three operators rushed onto a new machine with minimal setup instruction.

Jack pushes back. “So what,” he asks, “nobody’s accountable?”

Maria draws a distinction. Accountability isn’t the same as blame. The patterns they’re seeing don’t belong to one person. They belong to how work is planned, supplied, and taught.

This is the pivot Deming insisted on. In Out of the Crisis, he wrote, “The supposition is prevalent the world over that there would be no problems in production or in service if only our production workers would do their jobs in the way that they were taught. Pleasant dreams. The workers are handicapped by the system, and the system belongs to management.”

The supposition is prevalent the world over that there would be no problems in production or in service if only our production workers would do their jobs in the way that they were taught. Pleasant dreams. The workers are handicapped by the system, and the system belongs to management.

— W. Edwards Deming

That statement isn’t a moral judgment. It’s a diagnostic one.

Maria reframes the discussion in plain language. “First,” she says, “are things running the way they usually do? If they are, blaming the worker for random ups and downs doesn’t fix anything. Second, if something truly unusual happened—something you don’t normally see—then we treat it as a special cause and deal with it directly.”

They chart downtime and defects. Most of what they see sits inside predictable limits. One incident stands out clearly: a machine was deliberately bypassed after a safety interlock failed.

Jack agrees immediately. “That one’s on the person,” he says.

Maria agrees too. “Yes,” she says. “And because it’s clearly unusual, we can handle it firmly and directly—without pretending it explains everything else that’s been happening.”

Deming was explicit about this balance. “I should estimate that in my experience most troubles and most possibilities for improvement add up to proportions something like this: 94% belong to the system (responsibility of management) 6% special.” That six percent matters. It includes negligence, misconduct, and genuine inability. But treating ninety-four percent as if it were six is expensive.

I should estimate that in my experience most troubles and most possibilities for improvement add up to proportions something like this: 94% belong to the system (responsibility of management) 6% special.

— W. Edwards Deming

As Midwest Components changes its approach, conversations on the floor change as well. Supervisors stop asking who screwed up and start asking what conditions made outcomes likely. Training is stabilized. Scheduling is smoothed. Supplier variation is addressed. The one true special-cause issue is resolved and doesn’t need to be recycled as a warning story.

Performance improves—not because people suddenly became better, but because the system stopped working against them.

Where leaders get stuck

Most of us don’t blame workers because we enjoy it. We do it because it feels decisive. Someone must have caused the problem, and identifying that person creates a sense of action.

But when results are driven by the system, this habit quietly backfires. We demand explanations for normal ups and downs. We reward and punish based on noise. Fear increases. Stories replace learning. Leaders stay busy while the underlying causes remain untouched.

There’s also a subtler trap. When we believe outcomes are mainly about individual effort, we start to see disengagement as a personal flaw instead of a signal. We miss opportunities to redesign work so that success is the natural outcome, not a heroic one.

Deming warned against this explicitly when he urged leaders to eliminate slogans and exhortations. They create adversarial relationships, he argued, because the bulk of the causes of low quality and low productivity lie beyond the power of the workforce.

The result isn’t higher standards. It’s frustration on both sides.

Actionable Takeaways

The alternative to worker blame is not indulgence. It’s discipline.

Stop demanding explanations for routine variation. When things are running the way they usually do, stories won’t help. Improvement comes from changing the system, not interrogating individuals.

Make the distinction between common and special causes explicit. Leaders and supervisors should know the rules. When evidence shows the system produced the result, leadership owns the fix. When evidence shows a true special cause, address it directly and respectfully.

Redesign supervision around enablement. The job is not to motivate people to care more. It’s to make it possible for people to succeed through clear methods, adequate training, sensible workload, and timely feedback.

Treat pride of workmanship as a leadership responsibility. When barriers are removed instead of blame being assigned, problems surface earlier—when they are smaller, safer, and cheaper to fix.

These actions don’t lower standards. They raise them—by aiming effort where it actually matters.

The greatest waste in America is failure to use the abilities of people.

— W. Edwards Deming

Closing

Deming didn’t ask leaders to deny what they’ve seen. He asked them to look more deeply at it. Yes, some problems are caused by individuals. Far more are created by systems that quietly shape behavior, day after day, often without anyone intending harm.

There is something profoundly hopeful in this. Systems can be redesigned. Conditions can be improved. People who appear disengaged often surprise us when the work finally makes sense and success is possible.

“The greatest waste in America is failure to use the abilities of people,” Deming warned. When leaders shift from blame to understanding, organizations don’t get softer. They become more humane, more capable, and more effective.